Joanna Cosgrove, Contributing Editor04.26.24

There’s just something about the timeless allure of metal. For beauty brands, the use of metal packaging represents a tangible luxury that’s capable of attracting consumers with its cool luster and distinctive shine.

Beyond first impressions, metal packaging for beauty products offers functional benefits. Jars, tubes and bottles are impervious to contamination from light and air, and like glass, metal combines strength and durability with recyclability.

Likewise, metal closures also feel substantial in the hand. And whether they’re executed using actual metal or with plastic that’s been metallized and weighted to deliver the gleam and heft one would expect from a 100% metal closure, they can add a distinctive touch of whimsy to any package configuration.

According to a recent report from Transparency Market Research, the global metal caps and closures market is on track to be valued at $26.8 billion by 2031, registering a +3.6% CAGR from 2023 to 2031. Growth in the market, which was worth an estimated $22.4 billion in 2021, is projected to be driven by the increased use of sustainable raw materials in packaging solutions.

Analysts pointed to a combination of global environmental consciousness, and social and economic factors as drivers for metal options, as well as the growing perception of metal packaging as “fashionable.” Metal’s sustainability and inherent recyclability is another driving factor, with steel and aluminum leading the way, material-wise.

We spoke to metal packaging suppliers to ask about their capabilities, trends, and the appeal of shiny vessels for beauty consumers. Read on.

Anton Meindl, Executive Director of Sales, USA, Metapack, says metal primary packaging and componentry give products a winning and distinctive heft and shine. For fragrances, metal componentry has a luxurious feel and a heavier weight than plastic. For skin and personal care products, the incorporation of Zamac, stainless steel, and aluminum provides a high-end, tactile experience, giving a cooling effect when used to apply skincare products.

Metapack manufactures a variety of solutions for the fragrance, cosmetic, skincare, and personal care segments using various types of metals and manufacturing processes, and is now offering a proprietary specialized decoration application that provides the look of silk screening, hot stamping and pad printing on metal and glass. Meindl says the potential to create any decoration or logo is practically limitless and costs less than most inline deco applications.

One of Metapack’s most recent beauty endeavors was creating a collection of plastic-free, refillable packaging for La Bouche Rouge. The range’s aluminum makeup compact is molded in Zamac; covered with a white-lacquered, stainless-steel shell; and refillable without the use of magnets. The stainless-steel lipstick case is covered with recycled leather instead of plastic, and a plastic-free perfume cap made of Zamac with a custom inner cork replaces traditional plastic.

Metal applicators like metal-tipped wands and rollerballs are another way to incorporate metal into a package configuration. As a long-time staple in the wellness industry, these applicators are now being embraced by beauty and skincare brands for their cooling and massaging effects with products like eye, lip, face, lash and brow formulations. As a bonus, metal applicators are also hygienic and easy to clean.

Madeline Blondman & Co. Inc. recently introduced an innovative new aluminum cosmetic disc that prolongs product shelf life by acting as a barrier between the product and package lid. Randi Barron, President, says it is “a perfect blend of elegance and sustainability.”

“Nearly 75% of all aluminum ever made is still in use today,” says Barron. “Aluminum has one-third the density of steel. This means lighter packaging, lower energy consumption, and reduced emissions.”

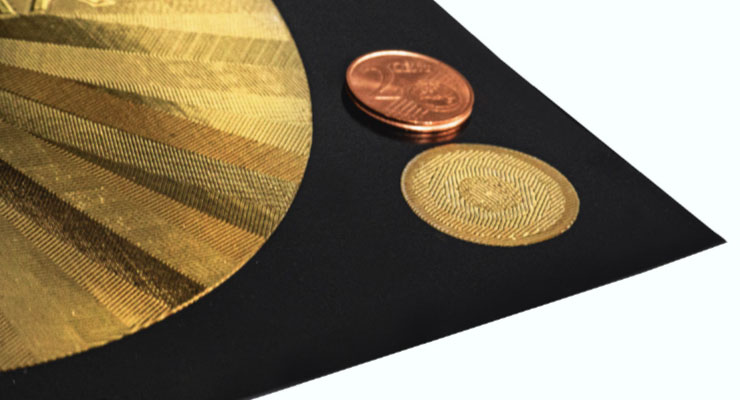

The new aluminum disc is completely customizable and embossable and comes in metallic color versions such as silver and gold. “Our aluminum component allows intricate designs and logos to be seamlessly embossed, adding a touch of sophistication to your packaging,” says Barron.

The aluminum disc is also completely recyclable, which Barron says is a big win for brands in search of packaging options that align with their eco-conscious values.

Aluminum was also a key consideration for Dior, which recently chose an aluminum precision applicator and tube configuration from Cosmogen for its latest wrinkle corrector, Capture Totale Hyalushot—and the entire package exudes luxury.

The “Needle Tube” is a high-shine aluminum tip tube that’s beautiful, and ensures peak preservation of the formula. It’s topped with a concentrated aluminum tip that’s specially designed for precision product application, depositing small quantities of concentrated product with near-surgical accuracy for targeting fine lines and wrinkles.

According to Cosmogen, the tip was inspired by professionals and is as “fine as a needle to target every wrinkle and remove them.” The tip is available in gold and silver versions, with an applicator that can be unscrewed and reused on a refill.

The product is finished with a matching cap that features an embossed CD monogram. The entire configuration was designed to harmoniously coordinate with Dior’s Capture Totale product line.

“The cold touch of anodized aluminum is part of the aesthetic code of the luxury industry,” says Beth Wicker, Account Manager, Anomatic.

Anomatic specializes in deep draw transfer press technology that enables the company to produce a large range of metal parts featuring various design elements such as embossed/debossed logo, stippling, tapering, sharp radius, beading/double beading and splines. “Our patented anodization process allows us to produce any color imaginable in several finishes meeting tight color ranges and consistency from part to part, and lot to lot,” says Wicker.

For packages without metal, Anomatic delivers premiumization through its eco-friendly, sputtering metallization technology. “We can transform basic plastic into an elegant, metallic look in any color, with varying opacity, and even in gradient designs,” Wicker says, noting that the quality of injection molding plays a role in the quality of the metallized parts, which Anomatic is capable of molding in-house.

Anomatic recently grew its eco-friendly stock range of two-piece, all-aluminum jar lids to include a mini 33/400 size (for 7mL jar). It joins the 40/400 (for 15ml jar) and 53/400 (for 50ml jar). The patented two-piece aluminum lid is 100% recyclable and can be produced using our exclusive eco alloy Evercycle, which is 100% recycled material, of which 94% is PCR.

“Everything about metal conveys luxury, including its sheen and weight,” comments Lindsay Panackia, Vice President of Sales, Metal Dynamics Inc. (MDI). “As far as decoration, whether you’re electroplating, vacuum plating, or anodizing a product, the process of metallizing automatically enhances its prestige and perceived value [because] we’re naturally attracted to brighter products that catch the eye,”

MDI provides a variety of metallizing processes including electroplating for zinc, brass and cast aluminum materials; vacuum plating for injection molded and die-cast components; and anodization, which is primarily used for aluminum componentry.

The company has worked with several well-known beauty and fragrance brands to create distinctive metallized looks. MDI has created electroplated and spray-coated Zamac caps for Caswell Massey and a uniquely metallized “armor” component for Valdé Beauty’s refillable lipstick packages.

One of the company’s most recent endeavors was the execution of a custom luxury compact for beauty brand, Trish McEvoy. “These compacts were manufactured using multiple parts to incorporate both metallized components and injection-molded colored components [which enabled] the customer to highlight specific details of the compact,” explains James Adelstein, MDI’s President/CEO. “Additionally, we designed a unique magnetic rug with hot-stamp metallized details.”

Adelstein says several engineering challenges arose during the process, not the least of which was ensuring multiple parts with varying specifications would function together smoothly. “The result was worth it,” he says, noting that the product earned a gold NJPEC award in December 2023 for its marketing impact.

Unifoil is already looking ahead to the forthcoming metal packaging trends for 2025-2026. David Peters, the company’s Global Product Development Director, says the emphasis will largely be on sustainable “beauty with shine,” with deeply reflective metallics and soft matte sheens adding on-shelf drama and amped-up brand sophistication.

Unifoil is the company behind Unilustre, an award-winning, transfer metallized process that’s plastic-free, UV-free and fully recyclable. The company’s new Unilustre Lens is a deeply reflective addition to Unifoil’s sustainable portfolio that delivers flawless silver and holographic patterns while balancing a brand’s sustainable initiatives. “Our Unilustre Lens is a fully sustainable and recyclable product crafted using 100% water-based adhesives and is free from any solvents or UV plasticizers,” Peters says.

He adds that Unifoil is currently working with a global beauty and skincare brand to outfit a new formula launch for optimum on-shelf standout. Peters says the product will make use of an exclusive Unilustre transfer metallization process to provide a silver surface for deep metallic detailing and intricate embossing features.

Gary Bibler, Director of New Creative Business at K Laser Technology (USA) Co., Ltd. says the allure of metal can be instantly communicative to consumers from the shelf or counter, which is ultimately advantageous to brands. “Creating dramatic packaging design helps increase the likelihood that people will pick up that product,” he says. “The consumer is not only experiencing the visual aspect but also the emotional feel of the packaging and brand.”

K Laser Technology offers full-coverage cold foil in solid colors and holographic patterns for the flexo and offset industry. “Registered custom hologram is a unique service providing a custom branded effect for our clients,” Bibler says, noting that the company also offers foil mock-up services. “All our holographic patterns and solid colors can be applied to our metallized board.”

Nerissa Ignacio-Littman, K Laser’s Creative Director, says the company’s registered holograms are a great option for unique, limited-edition packaging needs for holidays and anniversary products. “They can add a great sense of luxury and dimension to the packaging,” she says.

Viridian, K Laser’s lamination-free, full-coverage metallized boards, are another viable option for those times when cold foil cannot be placed on folded areas due to the potential for cracking. Ignacio-Littman says the boards are a solid solution that delivers on the premises of both flexibility and high quality.

Scodix is a specialist with digital embellishment presses and uses technology that allows for several different application methods of decorative finishing effects like foil, clear varnish and Cast&Cure semi-transparent holographic film, which can be applied either flat on the package or built up with tactile effects.

“[Cast&Cure’s] polymer technology makes the film more durable while also enhancing the brilliance of the film,” explains April Lytle, the company’s Regional Marketing Manager, U.S. “Because of the nature of the digital process, this allows for brands and designers to also use personalization in embellishment [such as] foiled or decorated names, numbering, or even variable artwork for a truly bespoke and customized experience.”

Scodix’s latest development is Smart High Definition (SHD) technology, which can mimic foiled micro-embossing, and an ART kit. “Smart High Definition allows for smaller text (foiled text down to five point in size) and extremely fine lines,” Lytle says. “It includes AI technology that will read the art files coming through and communicate with the print heads in how much polymer should be applied with lesser application on smaller areas to achieve detail never before seen in a digital embellishment process.”

The company’s ART kit makes it possible for brands to print on metallized board. “This has been especially popular and needed for collectible or competitive card decoration,” says Lytle. “At drupa 2024, we have even more announcements that will impact substrate, and even include some never-before-seen AI inclusion for ease of file set-up.”

Beyond first impressions, metal packaging for beauty products offers functional benefits. Jars, tubes and bottles are impervious to contamination from light and air, and like glass, metal combines strength and durability with recyclability.

Likewise, metal closures also feel substantial in the hand. And whether they’re executed using actual metal or with plastic that’s been metallized and weighted to deliver the gleam and heft one would expect from a 100% metal closure, they can add a distinctive touch of whimsy to any package configuration.

According to a recent report from Transparency Market Research, the global metal caps and closures market is on track to be valued at $26.8 billion by 2031, registering a +3.6% CAGR from 2023 to 2031. Growth in the market, which was worth an estimated $22.4 billion in 2021, is projected to be driven by the increased use of sustainable raw materials in packaging solutions.

Analysts pointed to a combination of global environmental consciousness, and social and economic factors as drivers for metal options, as well as the growing perception of metal packaging as “fashionable.” Metal’s sustainability and inherent recyclability is another driving factor, with steel and aluminum leading the way, material-wise.

We spoke to metal packaging suppliers to ask about their capabilities, trends, and the appeal of shiny vessels for beauty consumers. Read on.

Metal Packaging is Trending in Beauty

Across the beauty, personal care and fragrance brand spectrum, metal packaging is having a real moment thanks to the luxurious impression it creates.Anton Meindl, Executive Director of Sales, USA, Metapack, says metal primary packaging and componentry give products a winning and distinctive heft and shine. For fragrances, metal componentry has a luxurious feel and a heavier weight than plastic. For skin and personal care products, the incorporation of Zamac, stainless steel, and aluminum provides a high-end, tactile experience, giving a cooling effect when used to apply skincare products.

Metapack manufactures a variety of solutions for the fragrance, cosmetic, skincare, and personal care segments using various types of metals and manufacturing processes, and is now offering a proprietary specialized decoration application that provides the look of silk screening, hot stamping and pad printing on metal and glass. Meindl says the potential to create any decoration or logo is practically limitless and costs less than most inline deco applications.

One of Metapack’s most recent beauty endeavors was creating a collection of plastic-free, refillable packaging for La Bouche Rouge. The range’s aluminum makeup compact is molded in Zamac; covered with a white-lacquered, stainless-steel shell; and refillable without the use of magnets. The stainless-steel lipstick case is covered with recycled leather instead of plastic, and a plastic-free perfume cap made of Zamac with a custom inner cork replaces traditional plastic.

Metal applicators like metal-tipped wands and rollerballs are another way to incorporate metal into a package configuration. As a long-time staple in the wellness industry, these applicators are now being embraced by beauty and skincare brands for their cooling and massaging effects with products like eye, lip, face, lash and brow formulations. As a bonus, metal applicators are also hygienic and easy to clean.

Metal Tips for Tubes & More

The Metal Tip Collection from ICONS/ICS includes spatula, spiral, tapered and teardrop shapes, as well as bristle-free, spiral metal mascara applicators for lashes and brows, designed for precise and clump-free performance. The metal tip applicators are made of Zamac or stainless steel, which is known for its durability and compatibility with a wide variety of product formulations.Madeline Blondman & Co. Inc. recently introduced an innovative new aluminum cosmetic disc that prolongs product shelf life by acting as a barrier between the product and package lid. Randi Barron, President, says it is “a perfect blend of elegance and sustainability.”

“Nearly 75% of all aluminum ever made is still in use today,” says Barron. “Aluminum has one-third the density of steel. This means lighter packaging, lower energy consumption, and reduced emissions.”

The new aluminum disc is completely customizable and embossable and comes in metallic color versions such as silver and gold. “Our aluminum component allows intricate designs and logos to be seamlessly embossed, adding a touch of sophistication to your packaging,” says Barron.

The aluminum disc is also completely recyclable, which Barron says is a big win for brands in search of packaging options that align with their eco-conscious values.

Aluminum was also a key consideration for Dior, which recently chose an aluminum precision applicator and tube configuration from Cosmogen for its latest wrinkle corrector, Capture Totale Hyalushot—and the entire package exudes luxury.

The “Needle Tube” is a high-shine aluminum tip tube that’s beautiful, and ensures peak preservation of the formula. It’s topped with a concentrated aluminum tip that’s specially designed for precision product application, depositing small quantities of concentrated product with near-surgical accuracy for targeting fine lines and wrinkles.

According to Cosmogen, the tip was inspired by professionals and is as “fine as a needle to target every wrinkle and remove them.” The tip is available in gold and silver versions, with an applicator that can be unscrewed and reused on a refill.

The product is finished with a matching cap that features an embossed CD monogram. The entire configuration was designed to harmoniously coordinate with Dior’s Capture Totale product line.

Cold Foils, Holographic Patterns & More

Do you want the look of metal, but with more decorative flexibility? Metallization is the way to go.“The cold touch of anodized aluminum is part of the aesthetic code of the luxury industry,” says Beth Wicker, Account Manager, Anomatic.

Anomatic specializes in deep draw transfer press technology that enables the company to produce a large range of metal parts featuring various design elements such as embossed/debossed logo, stippling, tapering, sharp radius, beading/double beading and splines. “Our patented anodization process allows us to produce any color imaginable in several finishes meeting tight color ranges and consistency from part to part, and lot to lot,” says Wicker.

For packages without metal, Anomatic delivers premiumization through its eco-friendly, sputtering metallization technology. “We can transform basic plastic into an elegant, metallic look in any color, with varying opacity, and even in gradient designs,” Wicker says, noting that the quality of injection molding plays a role in the quality of the metallized parts, which Anomatic is capable of molding in-house.

Anomatic recently grew its eco-friendly stock range of two-piece, all-aluminum jar lids to include a mini 33/400 size (for 7mL jar). It joins the 40/400 (for 15ml jar) and 53/400 (for 50ml jar). The patented two-piece aluminum lid is 100% recyclable and can be produced using our exclusive eco alloy Evercycle, which is 100% recycled material, of which 94% is PCR.

“Everything about metal conveys luxury, including its sheen and weight,” comments Lindsay Panackia, Vice President of Sales, Metal Dynamics Inc. (MDI). “As far as decoration, whether you’re electroplating, vacuum plating, or anodizing a product, the process of metallizing automatically enhances its prestige and perceived value [because] we’re naturally attracted to brighter products that catch the eye,”

MDI provides a variety of metallizing processes including electroplating for zinc, brass and cast aluminum materials; vacuum plating for injection molded and die-cast components; and anodization, which is primarily used for aluminum componentry.

The company has worked with several well-known beauty and fragrance brands to create distinctive metallized looks. MDI has created electroplated and spray-coated Zamac caps for Caswell Massey and a uniquely metallized “armor” component for Valdé Beauty’s refillable lipstick packages.

One of the company’s most recent endeavors was the execution of a custom luxury compact for beauty brand, Trish McEvoy. “These compacts were manufactured using multiple parts to incorporate both metallized components and injection-molded colored components [which enabled] the customer to highlight specific details of the compact,” explains James Adelstein, MDI’s President/CEO. “Additionally, we designed a unique magnetic rug with hot-stamp metallized details.”

Adelstein says several engineering challenges arose during the process, not the least of which was ensuring multiple parts with varying specifications would function together smoothly. “The result was worth it,” he says, noting that the product earned a gold NJPEC award in December 2023 for its marketing impact.

Unifoil is already looking ahead to the forthcoming metal packaging trends for 2025-2026. David Peters, the company’s Global Product Development Director, says the emphasis will largely be on sustainable “beauty with shine,” with deeply reflective metallics and soft matte sheens adding on-shelf drama and amped-up brand sophistication.

Unifoil is the company behind Unilustre, an award-winning, transfer metallized process that’s plastic-free, UV-free and fully recyclable. The company’s new Unilustre Lens is a deeply reflective addition to Unifoil’s sustainable portfolio that delivers flawless silver and holographic patterns while balancing a brand’s sustainable initiatives. “Our Unilustre Lens is a fully sustainable and recyclable product crafted using 100% water-based adhesives and is free from any solvents or UV plasticizers,” Peters says.

He adds that Unifoil is currently working with a global beauty and skincare brand to outfit a new formula launch for optimum on-shelf standout. Peters says the product will make use of an exclusive Unilustre transfer metallization process to provide a silver surface for deep metallic detailing and intricate embossing features.

Metallized Glass and Paper

Foils, metallized films and spray coatings can also deliver the look of metal for plastic, paperboard and glass packaging configurations.Gary Bibler, Director of New Creative Business at K Laser Technology (USA) Co., Ltd. says the allure of metal can be instantly communicative to consumers from the shelf or counter, which is ultimately advantageous to brands. “Creating dramatic packaging design helps increase the likelihood that people will pick up that product,” he says. “The consumer is not only experiencing the visual aspect but also the emotional feel of the packaging and brand.”

K Laser Technology offers full-coverage cold foil in solid colors and holographic patterns for the flexo and offset industry. “Registered custom hologram is a unique service providing a custom branded effect for our clients,” Bibler says, noting that the company also offers foil mock-up services. “All our holographic patterns and solid colors can be applied to our metallized board.”

Nerissa Ignacio-Littman, K Laser’s Creative Director, says the company’s registered holograms are a great option for unique, limited-edition packaging needs for holidays and anniversary products. “They can add a great sense of luxury and dimension to the packaging,” she says.

Viridian, K Laser’s lamination-free, full-coverage metallized boards, are another viable option for those times when cold foil cannot be placed on folded areas due to the potential for cracking. Ignacio-Littman says the boards are a solid solution that delivers on the premises of both flexibility and high quality.

Scodix is a specialist with digital embellishment presses and uses technology that allows for several different application methods of decorative finishing effects like foil, clear varnish and Cast&Cure semi-transparent holographic film, which can be applied either flat on the package or built up with tactile effects.

“[Cast&Cure’s] polymer technology makes the film more durable while also enhancing the brilliance of the film,” explains April Lytle, the company’s Regional Marketing Manager, U.S. “Because of the nature of the digital process, this allows for brands and designers to also use personalization in embellishment [such as] foiled or decorated names, numbering, or even variable artwork for a truly bespoke and customized experience.”

Scodix’s latest development is Smart High Definition (SHD) technology, which can mimic foiled micro-embossing, and an ART kit. “Smart High Definition allows for smaller text (foiled text down to five point in size) and extremely fine lines,” Lytle says. “It includes AI technology that will read the art files coming through and communicate with the print heads in how much polymer should be applied with lesser application on smaller areas to achieve detail never before seen in a digital embellishment process.”

The company’s ART kit makes it possible for brands to print on metallized board. “This has been especially popular and needed for collectible or competitive card decoration,” says Lytle. “At drupa 2024, we have even more announcements that will impact substrate, and even include some never-before-seen AI inclusion for ease of file set-up.”