Marie Redding, Senior Editor04.30.19

Metal is luxurious—and metallic effects make a package sparkle, shine and attract attention. Beauty and fragrance brands are using metals and metallic effects on all types of packaging, from lipstick and jars to labels and boxes, in a multitude of ways.

“Consumers like the ‘eye appeal’,” says Anthony Di Maio, chief operating officer, Cameo Metal Products. “Metals and metallics stand out on shelf. There is no comparison to a plain color versus metallic, in terms of appeal,” he says, adding, “Metallic looks are associated with luxury goods—and convey ‘high value’ to consumers.”

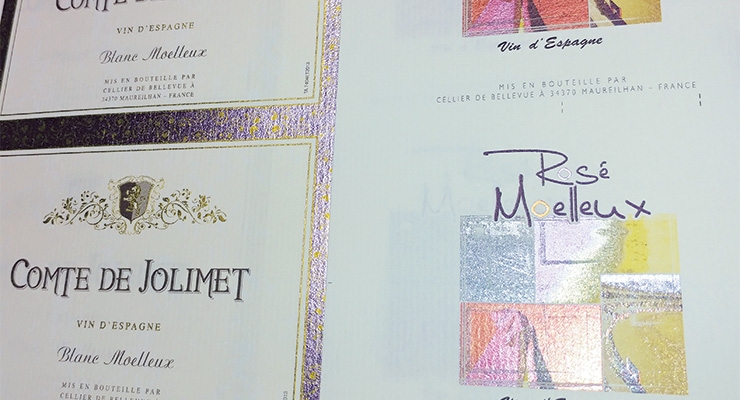

Jim Hutchison, president, Infinity Foils, Inc. and senior vice president, UEI Group, says, “Foil enhances a product’s ‘shelf appeal’ and influences purchasing decisions. When packages are tested side-by-side, the foil versions are preferred.” Infinity’s newest product is a line of digital foils.

“Metallics give a product a high-end look—it’s that ‘something extra’ that the consumer notices and equates with value,” comments Diane Pannizzo, sales, Overnight Labels.

Pannizzo credits the printing industry with being very responsive to trends in the market. “Printing technologies have advanced in recent years,” she says. “Not too long ago, we saw lots of basic laminations and soft-touch finishes, but there are many new developments now. We can do labels that feel like velvet, or have a sand-like texture—some of the latest options are pretty incredible,” she says.

Metal caps, as well as metallic finishes, are always on trend for luxury cosmetics and fragrances, notes François Damide, founder and CEO of Crafting Beauty, a company that works exclusively with Metapack. “Niche and luxury brands more often request heavier caps in gold or silver, specifically in zamac,” he says, explaining, “Paper and plastic labels are vanishing, and being replaced by high-quality metal plates, often in shiny gold zamac. The brand’s logo is often laser-engraved or debossed.”

Carlos Bragagnini, CEO, Amfora Packaging, says, “Brands today are not only metallizing, but the use of color is increasing—such as blue, red, copper, gold, and bronze.” Amfora Packaging specializes in the design, development, and production of containers and caps, decorating them using high-vacuum metallizing processes, digital printing, pad printing, labeling and painting techniques.

Advanced Solutions

As beauty brands fuel the need for packaging that shines with metallic features, suppliers are offering new solutions. One of Amfora’s specialties is metallizing glass, which is no easy task, the supplier says. Anomatic can now metallize a plastic hinge closure, which is an industry-wide innovation, the team says. Cameo Metal has the equipment to color-match “better than most,” says Di Maio.

Achieving a consistent metallic look across a range of materials and substrates is one of Overnight Labels’ specialties, and Pannizzo says she often works with brands to develop custom solutions. The team at Eagle explains its Cold Foil Certification.

Also, Kurz shares news about its digital foiling process for labels, which the company recently demonstrated at various events in partnership with HP. See the sections below for more on these suppliers and their capabilities.

Going for the Gold

Gold is a classic look for cosmetic packaging, especially lipstick. Bond No. 9 New York recently expanded from fragrance to makeup with the launch of its new lipstick line, New York Lips—and reinvented the lipstick case, giving it a new shape.

The team at Bond No. 9 New York created a custom shiny gold lipstick case with a curve, and it looks glamorous. “We wanted it to be a sexy shape—and to look and feel like jewelry,” says Laurice Rahmé, founder, Bond No. 9 New York. Plus, it’s refillable.

“The lipstick case’s curve is inspired by our fragrance bottle. It is beautifully designed and feels good in the hand. It also snaps shut with a satisfying magnetic click,” Rahmé explains.

The lipstick appears to be heavy, but it isn’t—and this was intentional. “We wanted it lightweight and easy to carry around, which wasn’t easy to do,” Rahmé says. “But even though it feels very light, it is not fragile. You can throw it in your bag—we made sure it will hold up. We used a metallization process—it is an aluminum alloy, dipped in shiny gold,” she says.

Rahmé says that making the case refillable was a must, adding, “If you are spending $105 on a lipstick, it should be refillable.” Refills, in a plain white tube, are $45. “We’ve always done refills—our customers love to come to the shop to refill their perfume bottles. It is better for the planet. You never have to throw our packaging away,” she says.

A gold charm that resembles a vintage NYC subway token hangs from the lipstick’s cap. The luxe white box is fitted with a custom tray and closes with a fancy gold latch. These details make it a beautiful gift.

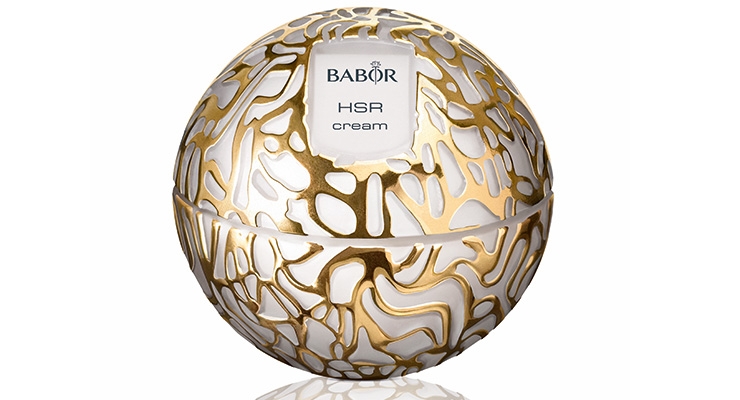

Brands are also adorning skincare packaging with metal and metallic gold designs. The team at Babor created a metal-like design in gold to give its orb-shaped skincare jar a luxe look.

The jar holds Babor’s HSR Lifting Extra-Firming Cream. “The bottom half of the jar is glass. The cap is plastic, and the gold design is made using a metallization process,” says Nicole Perau, marketing director, Babor. “The decoration was inspired by the collagen and elastin fibers in the skin,” she says.

Yellow gold may be a classic, but more beauty brands are choosing pretty pink and copper shades of rose gold, for both makeup colors and packaging. Winky Lux recently launched the Rosé All Day Kit, swapping its signature shiny yellow-gold lipstick pill-shaped case for a rose gold one.

Cameo’s Di Maio says rose gold is a color often requested. “I also see a big push for shinier finishes, versus matte looks that were popular last year,” Di Maio says, adding, “As a response to market demand, we created packaging options in a variety of shades, ranging from rose golds to coppers.”

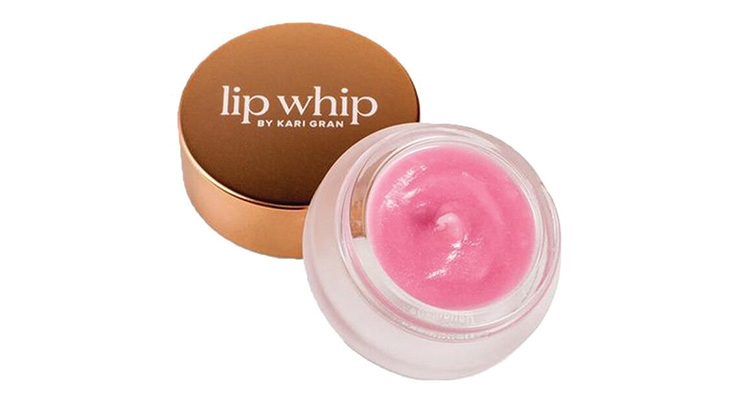

Di Maio recently worked with beauty brand Kari Gran. “We helped repackage Lip Whip lip gloss. We manufactured our 38/400 closure in a custom matte copper with a beautiful one-color deco on top in pink,” says Di Maio.

Colors for Metals & Metallics

Not to be outdone, silver looks equally upscale—and can elevate even the most ordinary product. Good Art Hlywd, a California-based jewelry company founded by designer Josh Warner, sometimes adorns beauty products with jewelry-inspired accessories. The brand’s website features a useful ring keychain cap that replaces ChapStick’s plastic cap.

Barney’s New York carries the brand’s fancy silver cap made to fit on a tube of Vaseline Lip Therapy. It is in the retailer’s new cannabis-themed lifestyle shop in its Beverly Hills store. Good Art Hlywd’s designs are handmade in sterling silver, and decorated with engraving and other techniques.

Metapack works with a variety of metals, such as steel, aluminum, and brass, often in silver and gold. The supplier produces different types of packaging and components including caps, collars and spray pursers for prestige fragrances, as well as compacts, lipstick cases, candle lids and plates. “Both matte and shiny finishes are trends for prestige fragrances, but matte is becoming more and more popular,” according to Isaure de la Noue, sales director, Metapack.

De la Noue says that on-trend plating colors include silver, gold, and gunmetal, for zamac, steel and brass products. “We’re noticing that more often brands are choosing light gold, which is called N1, instead of ‘regular’ gold, which is N2. They often combine gold with black finishing,” she says.

Metapack produced a line of solid perfume compacts for Diptyque. “The line shows our range of different finishing techniques, which include antique brass, copper and black. One compact combines zamac with PCTA,” says de la Noue.

Black can be made by lacquering or e-coating, de la Noue explains. “The antique look is trendy. We add patina on plating to give a component a vintage look.” Metapack often decorates metal plates with engraving, stamping, etching or laser processes. “Engraving can be filled with colored enamel,” she says.

Working with Foils & Finishes

Foils can instantly add flash or sparkle to every part of a package. What’s popular? “Rose gold, holographic, and matte colors have been wildly popular since last year,” says Todd Waxgiser, director of sales, Peyer America. “Gold, silver, and copper are also in demand, but in matte finishes,” he says. “We see these color trends across all product categories, including cosmetics, fragrance, hair care and body care products.”

When a beauty brand wants a custom look, requesting a custom foil color is an option. “I also see an increase in the use of custom foils. Some brands don’t want to choose traditional gold or silver,” says Waxgiser.

Winky Lux just launched the After Dark Blacklight Lip Crayon. The crayon is a UV lip balm for the lips, face or body, and it has a white label decorated with the brand’s logo in shiny foil. It comes in a pink box, adorned with mini gold lightning bolts printed with gold hot-stamped foil, which shine when they catch the light.

Infinity Foils’ products are found on a wide range of packaging in the beauty industry, including labels and containers. “We offer one of the largest ranges for the cosmetic industry,” says Jim Hutchison, the company’s president. “We offer metallics, pigment, pearl, scratch-off and holographic lines. We also have foils specifically formulated for stamping plastics, in a variety of grades and in a myriad of metallic shades.”

Infinity Foils’ products are ideal for cosmetics, since they are durable and have excellent scratch-resistance. They are often found on lipstick tubes, compacts and caps. “There is a multitude of different effects that can be created with foil,” says Hutchison.

“There are clear advantages to using these techniques on packaging; they attract the consumer’s attention faster, retaining attention longer, and brand awareness, to name a few,” he says, noting that past studies have found that packaging decorated with foil helps brands to stand out and increase ‘pick-up’ value. “Study participants indicated they perceived the packages with specialty effects to be of higher quality,” he says.

One decorating technique is to overprint on foil. “Our sister engraved-die companies–Universal Engraving, Inc. and UEI Falcontec–create dies and tooling for hot stamping and embossing,” Hutchison says. These companies manufacture the trademarked ‘Unifraxion’ dies that can enhance foil by combining fine line patterns in hot-stamping dies. “This process creates impactful, attention-getting works of art,” says Hutchison. “Unifraxion can also be customized to incorporate unique art or even a company logo. And to create texture and reflection, dies can be manufactured to create texture images like diamond plate by combining an embossing pattern with metallic foil,” Hutchison explains.

Peyer America’s Waxgiser often suggests different foils to brands, depending on the project and the look they are trying to achieve. “Finding the right type of foil for a specific application can be tricky,” Waxgiser says. The company has solutions for hot-stamping foils over a UV varnish. “Our 63TX foil series is available in many colors, including custom, and it is often used over a UV varnish on extruded tubes,” Waxgiser says.

Waxgiser advises brands to use Peyer America’s 63XO for over-stamping or over-printing. “This foil allows for greater design flexibility, for more complex artwork,” he says. If a project requires hot-stamping PP parts, Waxgiser suggests Peyer America’s 59HD quality foil series. “It’s perfect for closures, to match a container. This series includes our holographic foils, to give a package a certain panache,” he says.

A Toned-Down Metallic Look

Using foils doesn’t always mean ‘flashy’ looks. Overnight Labels’ Pannizzo says that when metallic foils are used on packaging, such as a label, applying a varnish or special finish over the foil will completely change its look—and can mute its ‘sparkle.’ “More brands are using metallics with softer finishes. This creates a more high-end look,” says Pannizzo. “I see a move away from super glossy shine,” she says.

Pannizzo says a toned-down look can be achieved by mixing matte finishes with foils. “Indie brands are using this style, successfully. Larger, established brands won’t change their look too often, no matter what the trends are,” she says.

Overnight Labels recently worked with Eden BodyWorks to produce labels for its hair care line. The labels feature a soft metallic finish. “We ‘matted’ the foil’s shine, for an understated elegance. A metallic foil label doesn’t always have to scream from the mountaintops,” she says. “I also see more brands choose brush foils, in place of highly reflective metallics,” Pannizzo adds.

“There are also new options in varnishes. Motion designs imprint a pattern into the varnish. And glitter varnishes add sparkle to a top coating,” she explains.

A Focus on Glitter

Many brands are opting for sparkling, high-shine looks, and that often means glitter, which has been a long-lasting trend. It is used for packaging, as well as makeup products and nail polish formulations.

Winky Lux’s paperboard palettes often sparkle with a glitter finish, including its Mini Uptown Kitten Palette in the Rosé All Day Kit, mentioned above. Several of the eye shadow colors inside sparkle, too. The brand’s Glimmer Balm, shown above, features suspended glitter in the bullet.

Infinity Foils offers decorative glitter. “Glitter is a fun way to add color and sparkle. Precision-cut and produced in popular colors and particle sizes, Infinity Foils’ glitters are available in a variety of colorful effects, including laser, metallic, rainbow, and fluorescence,” says Hutchison.

Eagle Advances Cold Foiling

Eagle Systems, which sells both hot-stamping and cold foil machinery, says cold foiling won’t ever replace hot-stamping, but it is a way to achieve an innovative look. And, it is being more widely used for packaging in the beauty industry.

“We’re seeing some brands applying standard cold foil to a carton with windows—and then again on the uncoated inside, so it shows through the windows. “This technique can create a brilliant shine,” says Michael King president and CEO, Eagle Systems. “Another decorating method, using cold foil, is to use uncoated stock for a box wrap or label,” King adds.

Eagle Systems perfected cold foiling on uncoated stock in 2015, and debuted the new technology to the industry the following year. “Since then, our partners are building this market. “It gives a package a very ‘rich’ look,” King says. He explains one way the process is different from hot-stamping, saying, “Hot-stamping flattens the grain in the paper stock, while cold foil takes the shape of the substrate.”

Eagle’s Cold Foil Certification includes extensive training for the supplier’s manufacturing partners. “Our certification is a major advantage—and brand owners recognize this,” King says. “It gives folks the knowledge needed to be able to refine the look of Cold Foil—and enable smooth running without chasing your tail during large production runs,” he explains, adding, “We have the ability to enable perfect consistency throughout the run, resulting in higher cost savings for brands.”

Digital Foiling and Labels

Kurz Transfer Products, which supplies a wide range of foils, says there are a multitude of benefits in choosing a digital foiling process over hot-stamping or cold foiling.

Digital foiling doesn’t require tooling or additional setup, unlike traditional metallic decorating methods.

“The capability to digitally print with a high-gloss metallic finish is a game-changer,” says April Lytle, marketing coordinator, Kurz Transfer Products. “Our DigitalMetal technology, when combined with the HP Indigo printers both inline or offline, makes it possible to apply metal foils in a similar fashion to ink,” she explains, adding, “It offers all the benefits of digital printing, including variable data, over-printability, serialization, and more. You can even incorporate holographic and security features.”

Kurz recently attended an event in Israel with HP Indigo to showcase its DigitalMetal process, working in-line with the HP Indigo 6900. The application equipment, the DM-Jetliner by Kurz, mounts upstream from the HP press and is designed to accommodate small to large production runs.

Once the labels or sheets are foiled, using Kurz DigitalMetal foils, they can be overprinted on the digital press, with endless color and design options, including personalization.

The printers can upload a nearly infinite number of variables, including images. Lytle says, “It’s exciting, because there has been such a high demand from consumers and brands for personalized options for packaging.”

Finishing Touches

Just as a varnish or finish can change the look of a label or carton, there are various decorating techniques that can change the color and look of a metal or metallized package, such as a lipstick or compact.

Anomatic, which specializes in metallization techniques, has introduced several new finishes that shine with glitter or fun confetti effects. “These decorative looks enable brands to utilize multiple colors in a very eye-catching finish,” says Steve Rusch, vice president, marketing and business development, Anomatic.

Rusch says etch-satin finishes are popular, along with a subtle gloss. “Typically, this is used in a double-anodization process, where two different surface finishes are combined to create a striking effect,” explains Rusch. “Brands will often elect to use a very bright logo on an etch-satin background to stand out in the marketplace.”

Anomatic introduced a major innovation in January 2019—flexible metallization for hinge closures.

“This is truly an innovation in the industry, and one that took our R&D team close to three years to develop” says Rusch. “The final product is a robust, flexible metallized finish that can withstand over 150 flips without delaminating or degrading the metallic finish along the hinge,” he explains, saying that “flips” refers to opening and closing the closure.

The proprietary technology provides the advantage of enhancing the closure’s surface durability. “Typical hinge closures delaminate rapidly, resulting in flaking that begins at the hinge, but frequently migrates across the product’s surface. To counter this common challenge, Anomatic leaned on its metallization expertise to produce a highly flexible finish with superior adhesion and very minimal degradation,” says Rusch.

One key aspect of this new process is any delamination that does occur over time is localized to the hinge area, and does not create flaking over any other area of the closure, Rusch explains. “As a result, hinge closures utilizing Anomatic’s high-flexibility finish retain a stunning appearance and functional performance throughout their life,” he adds.

Amfora Offers Advanced Techniques

Amfora Packaging specializes in producing and decorating all types of complex plastic components—and they also decorate glass.

Amfora’s Bragagnini, says, “Our ability to decorate glass using a high vacuum metallization process is what sets us apart.” He explains, “Metallizing glass for the cosmetics market is very tough to accomplish. We often combine this process with painting, for an upscale look.”

Amfora’s team has the ability to give glass bottles an innovative look using a translucent metallization technique. “The parts are metallized, but you can see through them. We have perfected the process of controlling the level of coverage, provided by the metal powder. We can achieve a beautiful translucent metallized effect in gold, for example,” Bragagnini says.

Another decoration the supplier provides is metallizing one part of a package, such as the back of a bottle, while leaving the front transparent. Bragagnini says, “We are known for our unexpected and unusual decorations, which are typically not often seen on the market.”

Color-Matching and Compatibility

The package development process is not often simple and glitch-free—and using metals and metallics requires planning for new sets of issues. “The biggest problem when working with metallics is trying to match a non-metallic substrate with an actual metal part. The backing on the substrate isn’t the same as raw metal, so the finishes are hard to match up,” says Cameo’s Di Maio.

Cameo Metal Products is one of the few manufacturers that uses an epoxy coating process, according to Di Maio. “This is why our color-matching is spot on,” he says. “We’re able to adjust a color slightly to create a variety of colors within the same hue in seconds,” he explains.

Metapack, which often produces metal plates and other components for fragrance bottles, says that the natural ingredients in fragrances can damage e-coating and plating. De la Noue advises, “We always test compatibility between bulk and finishing. If tests fail, we propose to use a varnish on top to protect the color.”

Peyer America offers options for matching foils for use across different materials, to ensure a consistent look. “We have solutions for popular plastics, including an ABS/SAN blend, glass, and metallized parts, to name a few,” says Waxgiser. He advises, “In order to develop a new foil solution, we have to know which material the foil will be hot-stamped onto, have a copy of the artwork, and the required testing. With more information from a brand, we can develop a better solution that will look and perform just as the designer envisions.”

When using a cold foil process, there are specific color-matching techniques that require a certain level of expertise, and Eagle has developed a reliable method for its cold foil machinery. “A color match can be locked in throughout the run. Matching through PMS colors on top of silver foils will keep your color consistent,” says King, advising, “When your adhesive background varies in density, your color will lighten or darken. A light-colored adhesive, matched close to the PMS, will give you better results, or use a clear adhesive for the most controlled color consistency.”

When working with foils on labels, Overnight Labels’ Pannizzo says each project is unique, but various decorating processes can be combined in different ways and every combination will result in a different look. “We have to consider each case one-by-one,” Pannizzo says.

She offers a final tip, “Choose a supplier that is up to the challenge of knowing which route to take, to best achieve the desired result.”

Makeup pans, used for pressed powders and hot pours, are typically pretty standard items, but Acme Cosmetic Components says brands often request innovative designs, such as a pattern on the surface of the makeup.

“We hear more requests lately for pans in shapes that support the product’s overall design, and have had a few requests for pans with customized surface finishes. These finishes either add performance or functionality, or enhance branding efforts,” says Mike Roughton, president and CEO, Acme Cosmetic Components.

Acme offers pans in two base metals: tinplate, which is steel electroplated with tin; or an aluminum alloy that is coated on both sides with a high-performance polymer. “We also provide smaller volumes in other metals, such as galvanized, which is steel that is zinc-coated as opposed to tin, or stainless steel,” says Roughton.

The use of metal pans, versus plastic, is better for the planet, says Roughton, and for a brand’s sustainability initiatives. “Metals are recyclable, and there are well-developed channels that already exist to ensure that metals do get recycled properly—and in a way that is convenient and understandable to the average consumer, as opposed to some other types of engineered paper or plastic,” he explains.

Specialized machinery is always required for various packaging processes, especially metallizing components.

Tapematic USA is a manufacturer of a specialized, fully-automated in-line decoration system. The company’s capabilities include cleaning/pre-treatment, applying primer and/or a base coat, metallization, in-line decoration, quality control inspection and full auto-loading and unloading.

As the system is modular, the user can effectively configure the line as they require, explains Tony Denning, president, Tapematic USA. Adding an in-line decoration module (IDM) is simple, and a useful feature, Denning explains.

“Our IDM can be positioned either pre-metallizing or post-metallizing, or both. Since the IDM is in-line, the last process is the top coat, and this ensures the package will stay protected, making it more likely to be free from defects. Waste, and secondary handling, are dramatically reduced,” Denning says.

Objects that are decorated pre-metallization produce a subtle embossing, while objects decorated post-metallization provide the decoration to the color of the base material.

“With over 50 lines installed worldwide, our PST Line is becoming the bespoke system of choice for companies that primarily specialize in cosmetic decorating, and want to expand production or add decorating capabilities,” says Denning.